Capabilities

Thick film hybrid circuit expertise

Thick film hybrid circuits offer compact, reliable, and temperature-stable designs. Ideal for harsh environments, they deliver consistent electrical performance over long life cycles.

With over four decades of focus in thick film microelectronics, Film Electronics brings deep expertise, strong process control, and proven reliability.

“Quality cannot be inspected into a product. It must originate with the initial design.” At FE, quality begins at the design stage—flowing through screen printing, laser trimming, and careful material handling. Our commitment: products that are on spec, on time, and built to last.

Custom design & development

FE’s R&D team brings robust, fast, and hands-on engineering support for your custom project. We work in sync with your team across all phases—from the first schematic to the final product.

1. Microelectronics design and layout

2. Miniature circuit package design

3. Schematic reviews & DFx analysis

4. Material and process recommendations

5. Testing, validation, and quality control

Every challenge is unique. Our team responds with solutions that are fast, focused, and feasible.

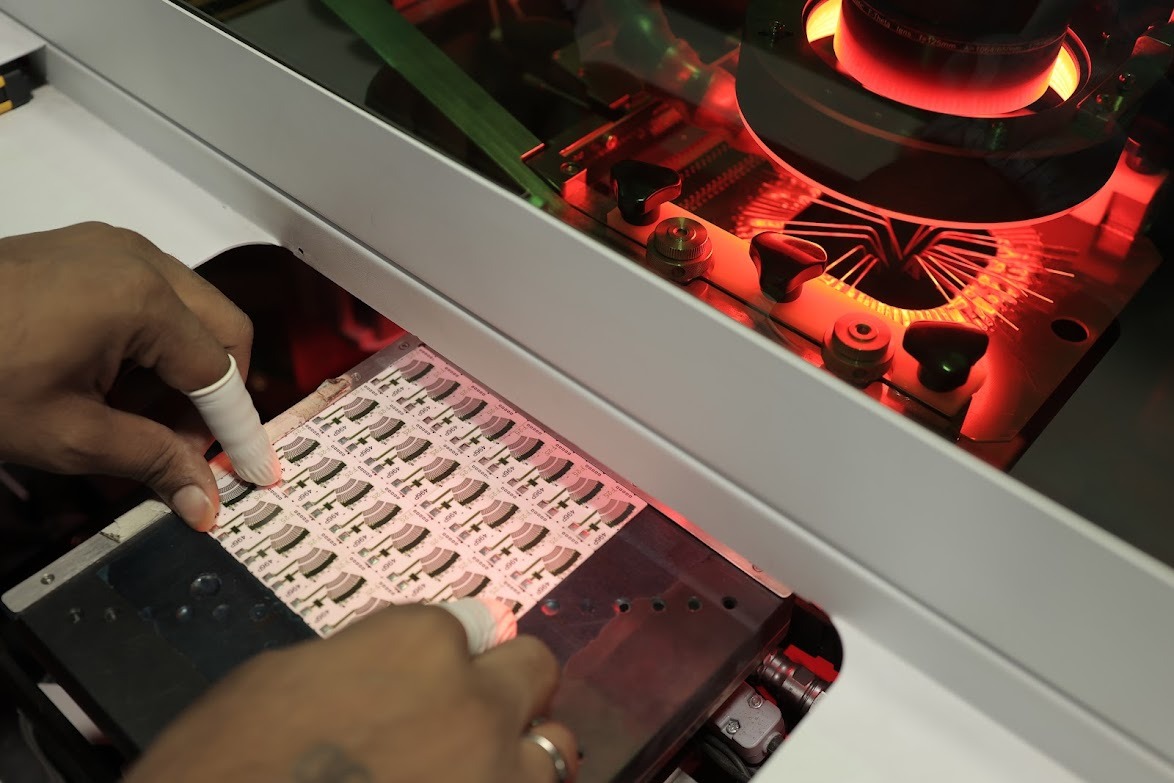

Advanced processing: Laser trimming, screen printing, EMS

In-house control over critical steps means better precision, repeatability, and turnaround.

Delivers precise resistor values for improved accuracy and calibration; cleanroom-grade process ensures stability; can achieve resistance tolerance ± 0.2%

Applies conductive, resistive, and dielectric pastes with consistency; supports complex multilayer ceramic circuits; can achieve printing widgth and gap of 0.15mm

High-speed pick-and-place with inline soldering, testing, and packaging; built to handle seamless volume production, mounting speed of upto 40000 componenets per hour

These aren’t just machines — they’re how we deliver your product right, the first time.

Great sourcing

Materials matter — and we’ve been sourcing them right for 40 years.

1. Genuine components

2. Lower BOM cost

3. Zero supply chain disruptions—ever.

1. 96% alumina ceramic substrates

2. Automotive-grade resistive(RuO2) & conductive inks (Ag, Ag:Pd, Ag:Pt)

3. High-performance LEDs for lighting modules

4. Passive & active components from certified vendors

With dual/multi-supplier strategy and decades of trust, we’ve ensured continuity even during global supply challenges.

Partnering for co-development

Let’s innovate together.

We partner with OEMs, Tier-1s, and system integrators to co-develop solutions that fit their unique needs—whether it’s a completely new design or optimizing existing systems.

1. Early feasibility analysis

2. Design iteration cycles

3. Prototyping & validation

4. Long-term production support